KwiTekhnoloji yokubonisa i-elekshini ye-elektroniki, umboniso we-LED usetyenziswa ngokubanzi kwimiqondiso yedijithali, umboniso wenqanaba, umhlobiso wangaphakathi kunye namanye amasimi ngenxa yokuqaqamba okuphezulu, ukuqaqamba okuphezulu, ubomi obude kunye nezinye izinto ezilungileyo. Kwinkqubo yokwenziwa kwemveliso yokukhutshelwa kwe-LED, itekhnoloji ye-engecPS likhonkco eliphambili. Phakathi kwawo, i-SMD ECOCTTRATIT yeTekhnoloji yeTekhnoloji ye-ECOCPS yeCob zine-engings ezimbini eziphambili. Ke, nguwuphi umahluko phakathi kwabo? Eli nqaku liza kukubonelela ngohlalutyo olunzulu.

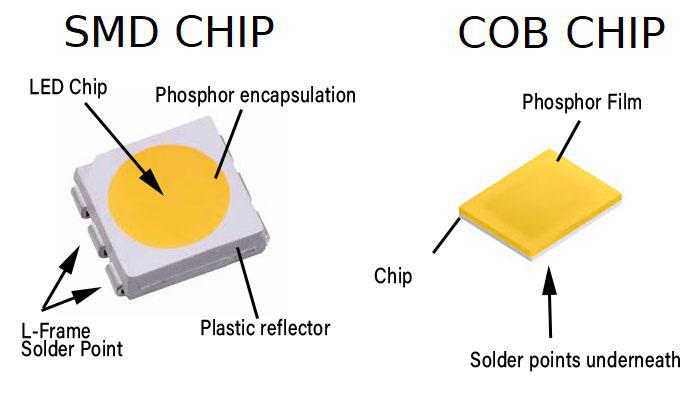

1.Yintoni itekhnoloji yokupakisha i-SMD, umgaqo wepakisi ye-SMD

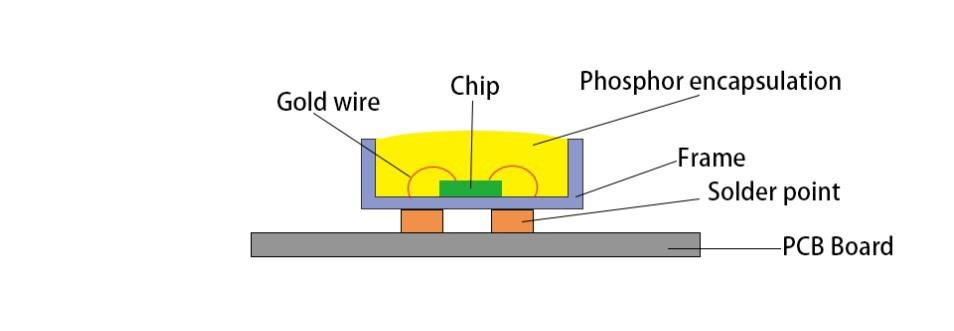

Iphakheji ye-SMD, igama elipheleleyo lokufikelela kwi-START (isixhobo esikhuselweyo), luhlobo lwezinto ze-elektroniki zidle ngqo kwiBhodi yeSiphaluka eprintiweyo. Iteknoloji yokubekwa endaweni yokubekwa i-POSTE YOKUGQIBELA, I-CHIP ye-EPPECK (ihlala inee-DITE ze-LED yokukhuphela kunye namacandelo asekwe kwi-APH kunye necandelo lesekethe elifunekayo) kunye nokurhweba ngokungxama kunye nezinye iindlela zokuqonda ukupakishwa kombane. Itekhnoloji yenza izinto ze-elektroniki zincinci, zikhanya ubunzima, kwaye zilungele ukuyilwa kweemveliso ze-elektroniki ezikhanyayo.

2. IInzo ezilungileyo kunye nokungalungi kweTekhnoloji ye-SMD

2.1 Izibonelelo zeTekhnoloji yeSMD

(1)ubungakanani obuncinci, ubunzima bokukhanya:Izinto zokupakishwa kwe-SMD zincinci ngokobukhulu, kulula ukudibanisa ukuxinana okuphezulu, kulungele uyilo lweemveliso ze-elektroniki ezincinci kunye nezikhanyayo.

(2)Iimpawu eziPhakamileyo eziPhezulu:Izikhonkwane ezimfutshane kunye neendlela ezimfutshane zoqhagamshelo lunceda ukunciphisa ukungahambi kakuhle nokuxhathisa, ukuphucula intsebenzo esemva kwexesha.

(3)Ilungele ukuveliswa okuzenzekelayo:Ilungele ukuveliswa komatshini wokubekwa ngokuzenzekelayo, ukuphucula ukusebenza kwemveliso kunye nokuzinza komgangatho.

(4)Umsebenzi olungileyo we-thermal:Ukunxibelelana ngokuthe ngqo nomphezulu wePCB, ofanelekileyo kwi-Heat Strasipation.

2.2 Ukupakisha itekhnoloji ye-SMD

(1)Ulondolozo oluntsonkothileyo: Nangona indlela yokufumana indawo esemgangathweni yenza kube lula ukulungisa kwaye kuthathelwe ingqalelo izinto, kodwa kwimeko yokudityaniswa koxinano oluphezulu, ukutshintshwa kwezinto ezithile kunokubakho ngakumbi.

(2)Indawo yokulahla inkunkuma yasebusika:Ngaphezulu kwe-pad kunye nokuchitheka kobushushu bejeli, umsebenzi omde umsebenzi ophezulu unokukhokelela kubushushu uxinzelelo, echaphazela ubomi benkonzo.

3.Yintoni itekhnoloji yokupakisha ye-cob, umgaqo wepakethi

Iphakheji ye-COB, eyaziwa ngokuba yi-chip kwibhodi (i-chip kwibhodi yebhodi), yi-Bare chip ye-Bip kwiTekhnoloji yokupakisha iPCB. Inkqubo ethile yi-chip ye-bare Ingcinezelo yobushushu, i-chip's i / o terminals kunye neepads zePCB ziqhagamshelwe, kwaye ekugqibeleni zitywinwe kunye nokukhusela i-resin. Oku kucekeceka kuphelisa i-LEAP ye-LEAP ye-LEAP ye-LEAP ye-LEAP, esenza iphakheji ngakumbi i-compact.

4.Izibonelelo kunye nokungalunganga kwetekhnoloji yokupakisha ye-cob

4.1 Izibonelelo zeTekhnoloji yeTekhnoloji

(1) Iphakheji yecompact, ubungakanani obukhulu:Ukuphelisa izikhonkwane ezisezantsi, ukufezekisa ubungakanani bephakeji encinci.

(2) Ukusebenza okuphezulu:I-wire yegolide edibanisa i-chip kunye nebhodi yesekethe, umgama ohambisa umqondiso mfutshane, ukunciphisa i-crostalk kunye ne-frostalk kunye neminye imiba yokuphucula intsebenzo.

.I-chip ifudukele ngokuthe ngqo kwi-PCB, kwaye ubushushu buyekwe kwiBhodi ye-PCB yonke, kwaye ubushushu buyekile ngokulula.

(4) Ukusebenza okuqinisekileyo:Uyilo oluvalelweyo oluvalelweyo, ukuxhonywa ngamanzi-bungqina, ubungqina bothuli, i-anti-static kunye neminye imisebenzi yokhuseleko.

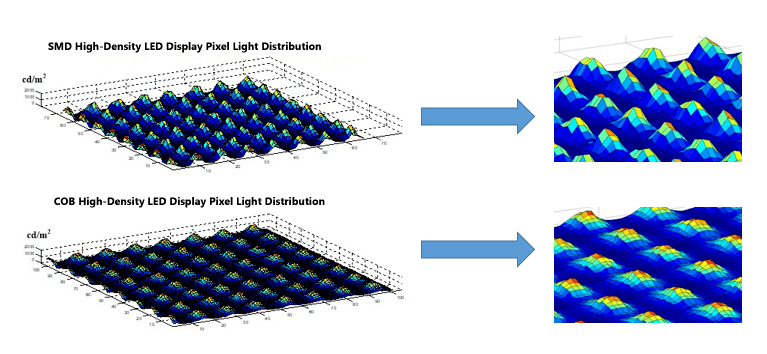

(5) Amava afanelekileyo abonakalayo:Njengomthombo wokukhanya ongaphezulu, ukusebenza kombala kucacile, ukulungisa ngakumbi iinkcukacha, kufanelekile ukujonga ixesha elide ngokusondeleyo.

4.2 I-Cob yokupakisha itekisi

(1) Ubunzima bokugcina:I-CHIP kunye ne-PCB ngqo ye-welding, ayinakubakho ngokwahlukeneyo okanye ibuyise i-chip, iindleko zokulungisa ziphezulu.

(2) Iimfuno zemveliso ezingqongqo:Inkqubo yokupakisha yeemfuno zokusingqongileyo iphakame kakhulu, ayivumeli uthuli, umbane oqingqiweyo kunye nezinye izinto zongcoliseko.

5. Umahluko phakathi kwetekhnoloji yokupakisha ye-SMD kunye netekhnoloji yokupakisha

Itekhnoloji ye-SMD ESECK NEECRALT TECTAT PAYCTE Oku kulandelayo ngumdlalo ocacileyo kunye nohlalutyo:

5.1 Indlela yokupakisha

Itekhnoloji yokupakisha i-⑴SMD: Igama elipheleleyo sisixhobo esikhuselweyo, esiyitekhnoloji yokupakisha abo bathengisa i-chip eprip eprintiweyo kumphezulu weBhodi yePatch eprintiweyo. Le ndlela ifuna i-chip ye-LED ukuba ifakwe kwangaphambili ukwenza icandelo elizimeleyo kwaye libekwe kwi-PCB.

Itekhnoloji yokupakisha i-⑵cob: Igama elipheleleyo yi-chip kwibhodi, eyitekhnoloji yokupakisha eya kubathengisi ngokuthe ngqo i-chip engenanto kwi-PCB. Isusa amanyathelo okupakisha ye-Lamps ye-LED ye-LED, ibopha ngokuthe ngqo i-chip engenanto kwi-PCB eneglue enomgangatho ofanayo okanye odibeneyo, kwaye uyayiqonda uqhawulo-mbane.

5.2 ubungakanani kunye nobunzima

Ukupakishwa kwe-RSMD: Nangona izinto zincinci ngokobukhulu, ubungakanani babo kunye nobunzima busekhona ngenxa yobume bepakethi kunye neemfuno zepad.

Iphakheji ye-⑵cob: Ngenxa yokushiywa kwezikhonkwane ze-pins kunye nephakheji yephakheji, iphakheji ye-COB ifezekisa ukungcola okukhulu, ukwenza iphakheji incinci kwaye ilula.

5.3 Umsebenzi wokuSebenzisa ubushushu

Ukupakishwa kwe-⑴smd: ubukhulu becala ichitha ubushushu ngamaplanga kunye ne-colloids, kunye nendawo yokutshisa ubushushu incitshisiwe. Ngaphantsi kokukhanya okuphakathi kunye nemithwalo ephezulu, ubushushu bunokujongwa kwindawo yeChip, buchaphazela ubomi kunye nokuzinza kwesibonisi.

Iphakheji ye-⑵cob: i-chip idlule ngokuthe ngqo kwi-PCB kunye nobushushu inokuchithwa kwiBhodi ye-PCB yonke. Lo uyilo oluPhucukileyo luphucula ukuSebenzisa ubushushu bokubonisa ubushushu bomboniso kunye nokunciphisa umgangatho wokusilela ngenxa yokuthatha inxaxheba.

5.4 Ukulula kolondolozo

Ukupakishwa kwe-RSMD: Kuba amacandelo aphakame ngokuzimeleyo kwi-PCB, kulula ukutshintsha icandelo elinye ngexesha lolondolozo. Oku kuyandinceda ukunciphisa iindleko zesondlo kwaye kunciphise ixesha lokulungisa.

Ukupakishwa kwe-⑵cob: Kuba i-chip kunye ne-PCB iphinde yenziwa ngokuthe ngqo, ayinakwenzeka ukuba isebenze okanye ithathe indawo ye-chip ngokwahlukeneyo. Nje ukuba isiphoso siyenzeka, idla ngokuba yimfuneko ukuba ithathe indawo yonke ibhodi ye-PCB okanye ibuyise kumzi-mveliso wokulungiswa, owonyusa iindleko kunye nobunzima bokulungisa.

5.5 Imeko yesicelo

Ukupakishwa kwe-⑴smd: Ngenxa yokuvuthwa kwayo phezulu kunye neendleko eziphantsi zemveliso, ngakumbi kwiiprojekthi ezinobuthathaka kakhulu kwaye zifuna ukuba lula iibhodi eziphezulu kunye neendonga zeTV zangaphakathi.

Ukupakisha okuphezulu kwe-⑵cob: Ngenxa yokusebenza kwayo ephezulu kunye nokukhuselwa okuphezulu, kubaluleke ngakumbi kwizikrini eziboniswayo, zilungele ukubeka esweni amagumbi kunye neminye imiboniso kunye neminye imimandla ephantsi. Umzekelo, kumaziko omyalelo, ama-stuos, amaziko amakhulu athumelayo kunye nezinye izinto ezihlala zibukela isikrini ixesha elide, itekhnoloji yokupakisha i-POB inokubonelela ngamava abuthathaka kwaye abuthathaka.

Ukuqukumbela

Itekhnoloji yokupakisha ye-SMD kunye netekhnoloji yokupakisha i-SMO nganye ineengenelo zawo ezizodwa kunye nemeko yesicelo kwicandelo lesikrini sokubonisa esidleleni. Abasebenzisi kufuneka banobubele kwaye bakhethe ngokweemfuno zokukhetha xa ukhetha.

Itekhnoloji yokupakisha ye-SMD kunye netekhnoloji yokupakisha i-POB ineengenelo zazo. Itekhnoloji yokupakisha i-SMD isetyenziswa ngokubanzi kwimarike ngenxa yokuqola kwayo kunye neendleko eziphantsi zemveliso, ngakumbi kwiiprojekthi ezinobuthathaka kakhulu kwaye zifuna ukuba lula. Itekhnoloji yokupakisha i-Cob, kwelinye icala, ikhuphisane kakhulu kwizikrini zokubonisa i-Indoor ephezulu, imiboniso yoluntu, igumbi lokuhlola kunye nezinye izinto ezinomsebenzi ophezulu, ukusebenza kobushushu, kunye nokusebenzela okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokusebenza okuqinisekileyo kobushushu kunye nokukhusela ubushushu.

I-Post Time: Sep-20-2024